1. Running Mode

(1) Fwd/Brk; (2) Fwd/Rev/Brk; (3) Fwd/Rev.

All vehicles: (3) Fwd/Rev

(Unless you want brakes, in which case select (2) Fwd/Rev/Brk)

For a crawler, you want (3) Fwd/Rev. For a trail rig, you might want (2) Fwd/Rev/Brk if you want braking before changing directions, but most people will prefer (3) Fwd/Rev for all crawler and trail truck types. Racetracks with brushed motor vehicles are a rarity these days (often the ‘Classic’ class), but if you are using this ESC on a racetrack rather than in a crawler, (1) Fwd/Brk is the only one you’d generally be allowed. That isn’t relevant to us though! Most of the time, (3) Fwd/Rev is the answer here.

2. Battery Type

(1) LiPo; (2) NiMH.

Set according to your battery type.

This basically gives you a lithium-polymer (‘LiPo’) low-voltage cut-off. The cut-off function protects your lithium battery from sustaining damage from over-discharge. Such a circuit isn’t needed for nickel metal-hydride (‘NiMH’) batteries. So, simply select the option for the battery chemistry you’re using: that’s LiPO, for most of us, or NiMH if not.

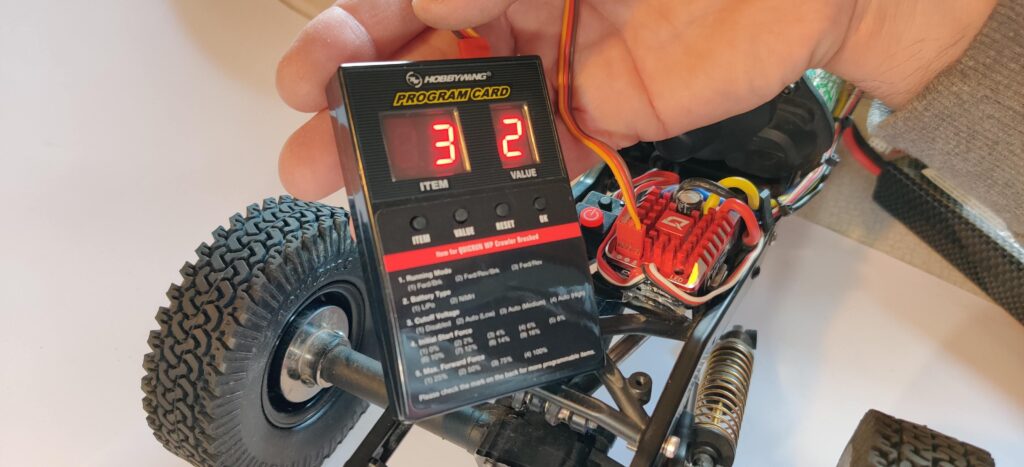

3. Cutoff Voltage

(1) Disabled; (2) Auto (Low); (3) Auto (Medium); (4) Auto (High).

All trucks: (2) Auto (Low)

(Or (3) according to personal preference. See explanation below).

If you selected (2) NiMH on Battery Type, this setting must be (1) Disabled. Otherwise, what you select here will be determined by your approach to managing your LiPOs. I’ve been using LiPOs for over a decade and have over 100 of them in many sizes. (2) Auto (Low) is fine in my opinion, as once you’re done with the rig the battery will go onto Storage charge when you’re done with it anyway.

Many folks have opinions on LiPO batteries and that includes me: I’ll just say that the individual cells can take the stress of hitting 2.5v and lower for short periods of time. The lower you go, the more you risk damaging the chemical balance in the cells. However, the ‘Low’ setting here is 3.0v so you’re going to see voltage sag to about 2.7v for brief periods with it on (2) Auto (Low), which is acceptable, in my opinion.

One caveat to my strategy: if you’re away from a charger for a while and won’t be able to put the battery on Storage for a few days, then go with (3) Auto (Medium) instead. This will be a bit kinder to your cells. Going with (4) Auto (High) actually cuts off at around storage charge, which is simply too high, IMO. I don’t think (4) Auto (High) is really ever needed unless you’re using a teeny, tiny battery of very low discharge potential; but in that case, it’d be the wrong kind of battery for a crawler anyway! So, ignore option (4) and go with (2) or (3) if you’re more comfortable.

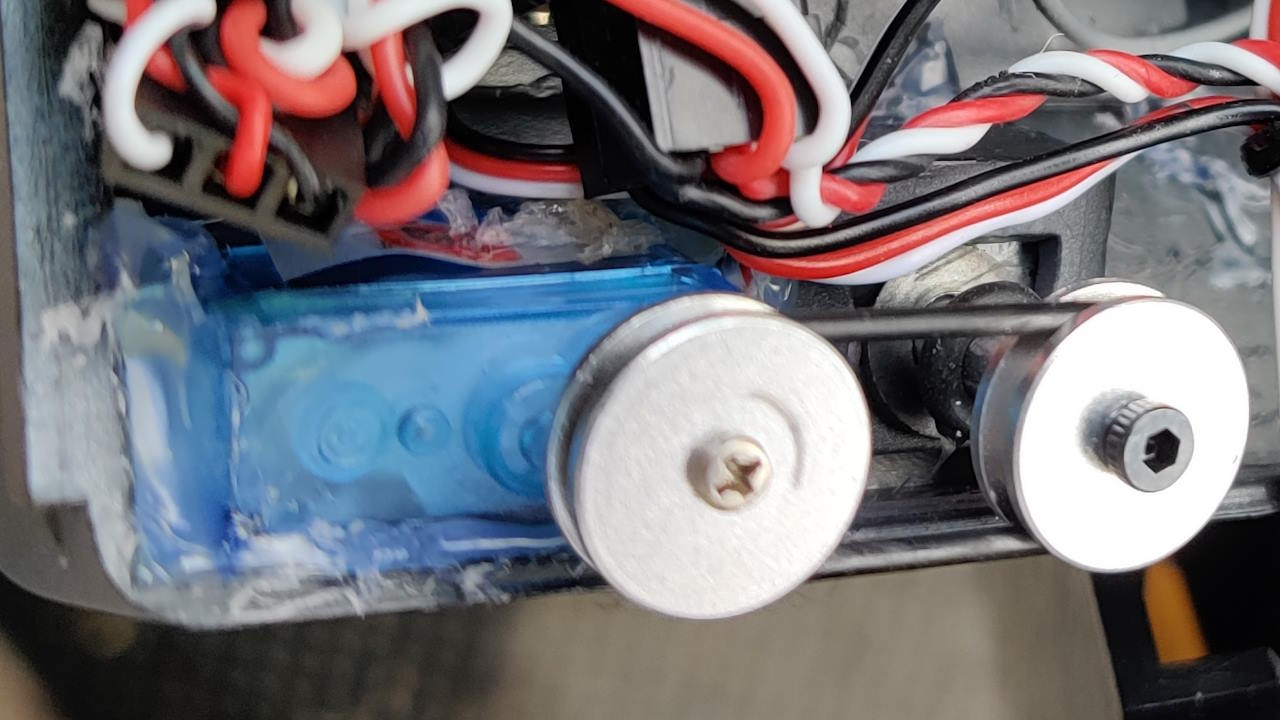

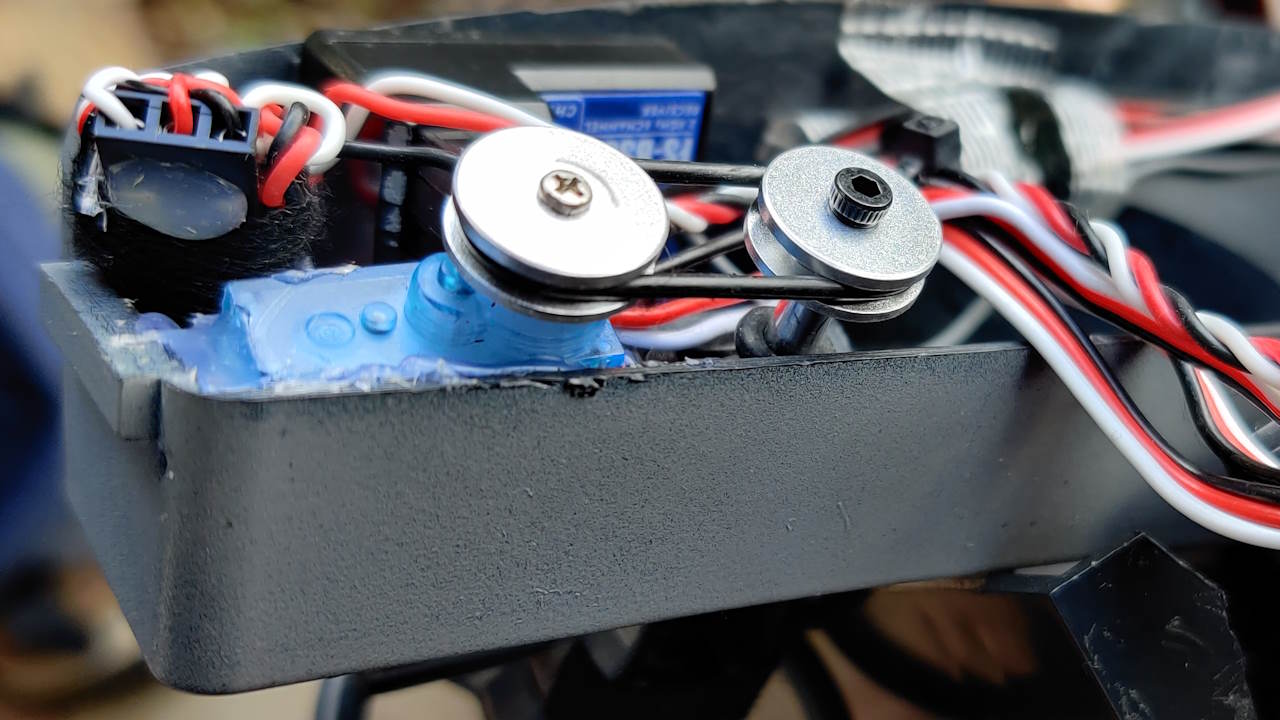

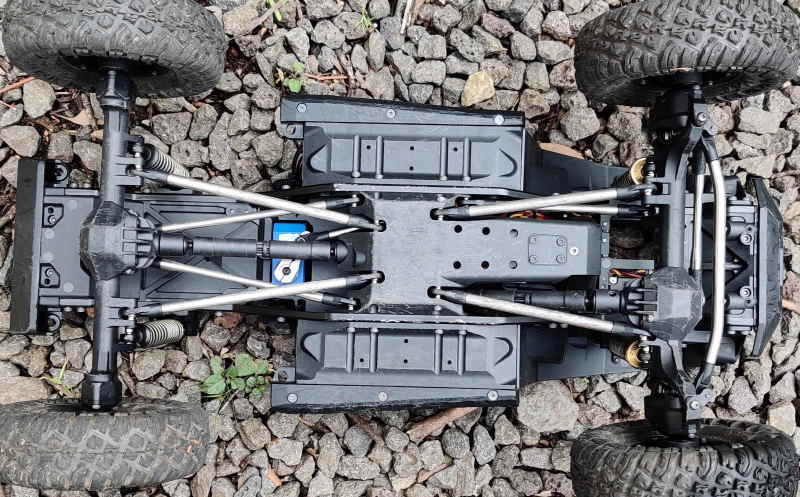

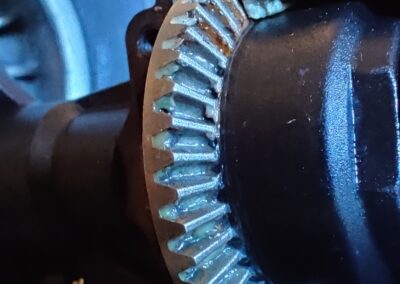

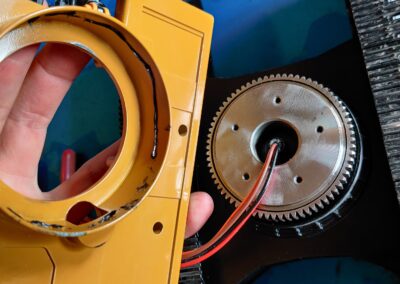

Could you give some information how to install the RCRun RUN80 steering wheel servo? I’ve got my kit and for the steering module there are only two alloy pullies and the micro servo. No frame for the servo or other stuff. I hope you could help. Ty from the other end of the rc world (germany) 😉