How to Program HobbyWing Fusion RTR ESC?

April 2024 – various video comments

Redcat Ascent Fusion: How do you program the HobbyWing Fusion RTR ESC? (or, how to program the HobbyWing Fusion Crawler ESC).

HobbyWing Fusion RTR ESC Programming

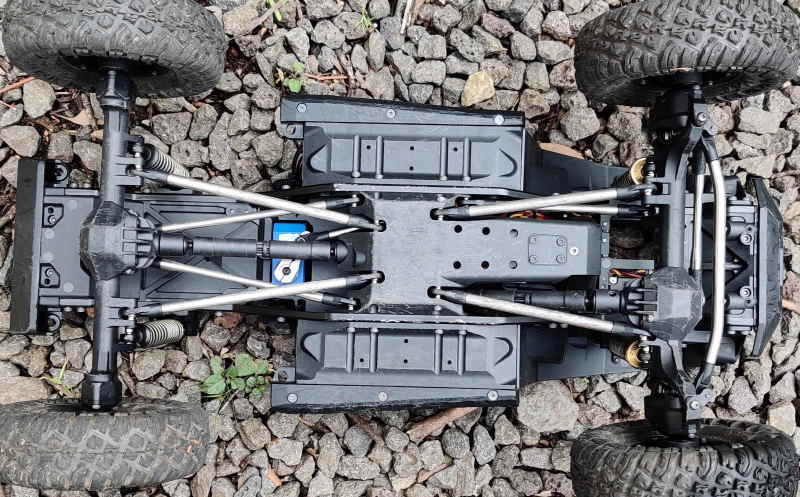

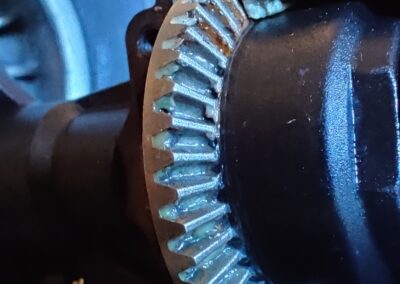

A. There are three variants of the HobbyWing Fusion now: the Fusion Pro 2300kv, the Fusion SE 1800kv and 1200kv, and the Fusion RTR (aka. Fusion Crawler) 1800kv. It’s the Fusion RTR that ships with the Redcat Ascent Fusion, and we’ll probably see this OEM-supplied unit in other RTR models in future, too.

You can use any of the programming cards from the HobbyWing WP-1080 ESC (and we have a programming guide for all crawlers for the WP-1080 here), the HobbyWing Fusion Pro, or the HobbyWing Fusion SE. It’s the ESC itself that dictates what each menu does, regardless of the sticker on your programming card.

HobbyWing Fusion RTR ESC Programming Menu

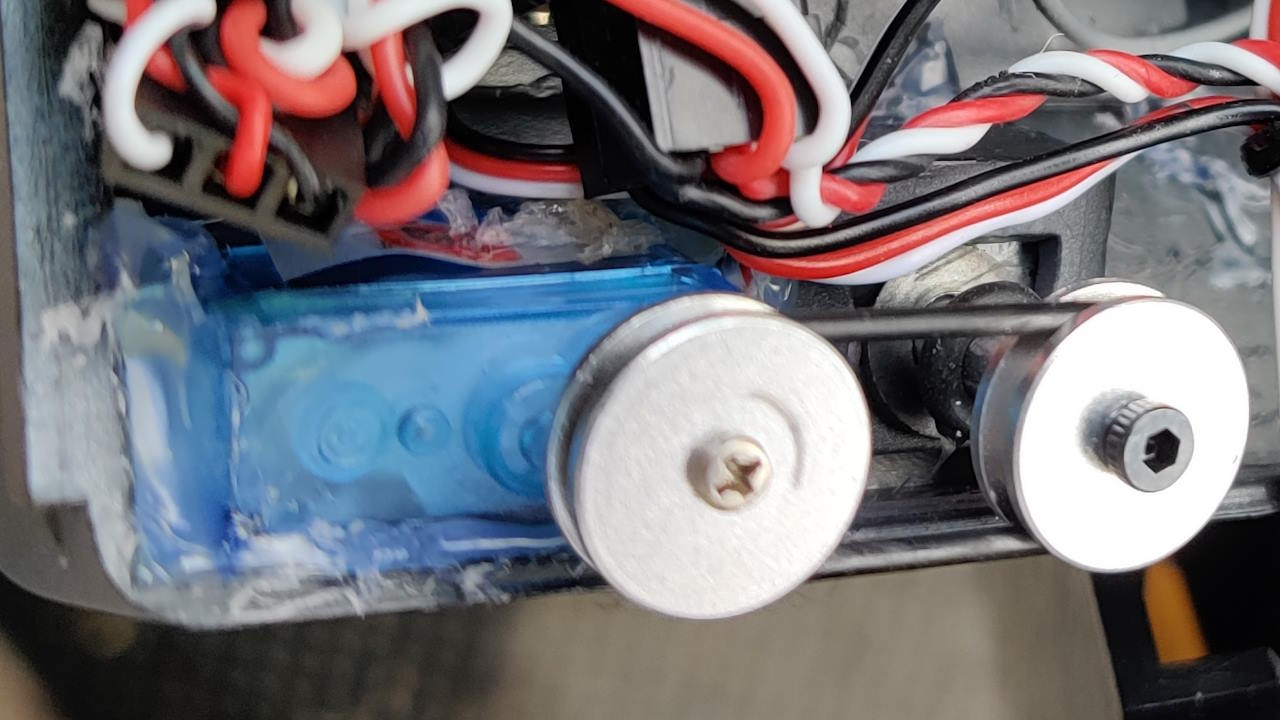

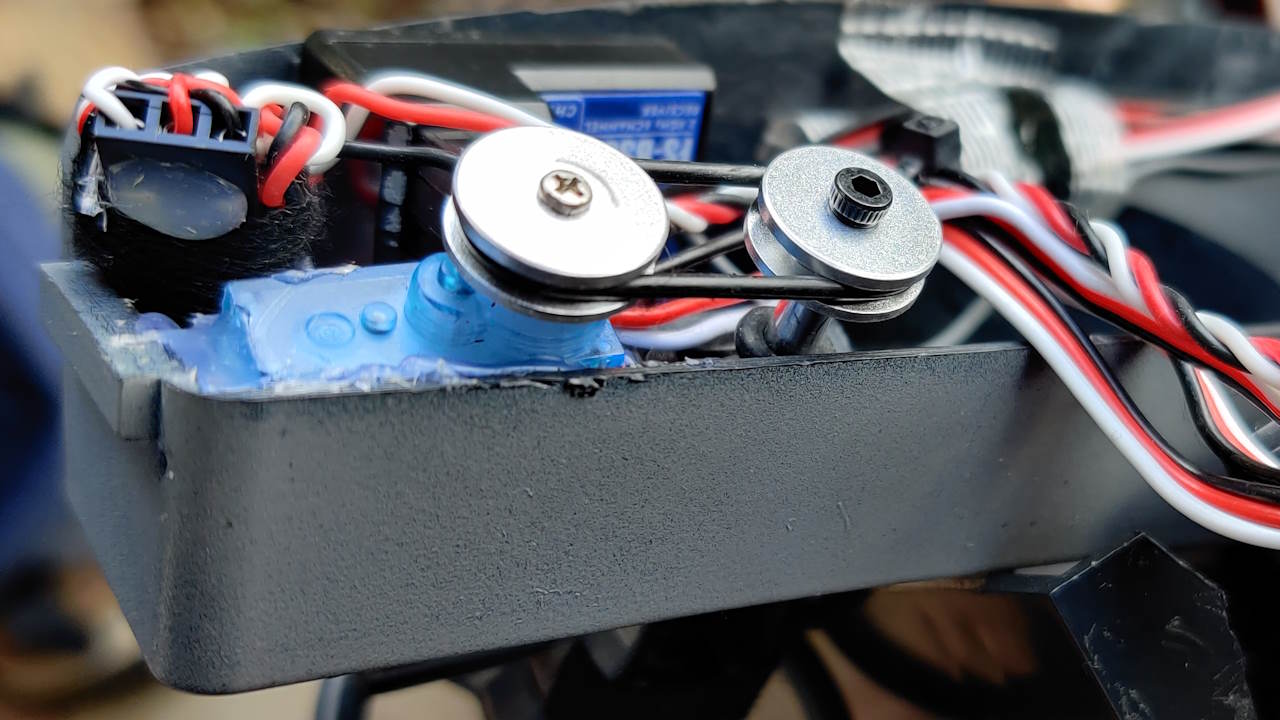

First, remove the rubber water shield on the power button module and plug in your HobbyWing programming card. There’s an illustration to show signal, +ve and -ve (white, red and black, in that order).

Press Power to turn the ESC on. The card’s red digits should illuminate. Here’s what each menu item is:

- Low-Voltage Cutoff (LVC) for LiPO batteries (1-4; 1 is Disabled (for NiMH batteries), 2-4 is low-high, maybe 2.7v, 3v and 3.3v at a guess);

- Motor Rotation (1 CW, 2 CCW);

- Drag Brake Force (1-5; 1 is off; 2-5 weak-strong drag brake);

- Drag Brake Rate (1-6; slow-fast application of drag brake).

Press Item to cycle through 1 to 4, Value to cycle through the item options, then when you’re done with all of them, press OK to save.

Press the power button to turn off the system.

Unplug the programming card, replace the rubber water sheild, and power up – you’re ready to test!

Craig Veness

RC-TNT

Craig has been into radio control since the 90s and into RC crawling since about 2010, when a Losi MRC started the obsession! Now it's all rocks this and crawl that and upgrade all the things! ...You know how it is, right? Welcome home 🙂

Could you give some information how to install the RCRun RUN80 steering wheel servo? I’ve got my kit and for the steering module there are only two alloy pullies and the micro servo. No frame for the servo or other stuff. I hope you could help. Ty from the other end of the rc world (germany) 😉